Integration and success guaranteed with ALOER

ALOER is a long-standing integrator partner of the Infor Cloudsuite Supply Chain Planning (SCP) software suite, and an expert in all modules of Cloudsuite SCP, the supply chain solution from the American publisher Infor.

While IT tools are essential today to support flows and Supply Chain Management, ALOER has selected those on the market that meet the needs of industrial and food industry players:

- specialized in their field: best-of-breed

- a reliable publisher that invests heavily in software development

- with international coverage and support

ALOER offers its expertise in implementing these strategic management approaches.

From organizational recommendations to the implementation of specialized supply chain tools, we are at your side to contribute our experience and know-how.

Discover the power of the Infor Supply Chain Planning software suite

The integrated planning software suite supports companies in creating, managing, collaborating and coordinating planning throughout the supply chain.

The full spectrum of Cloudsuite SCP extends from sales forecasting to workshop scheduling, and consolidates both strategic and operational planning.

Discover below the philosophy behind the modules of the Infor Supply Chain Planning software solution — dedicated to Supply Chain.

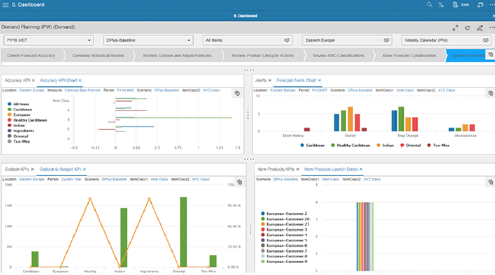

Sales forecasts — Demand Planning: Anticipate demand with precision

Demand Planning’s priority is to alert the forecaster at each period to the items for which his expertise is needed. For other items, powerful algorithms reduce the need for monthly and manual revisions.

The module’s library of algorithms makes it possible to adapt forecasts according to product sales behavior: seasonal or intermittent, new products or end-of-life, or so-called “erratic” products. These algorithms can also be applied to the past, to correct historical behavior during recent major events. The system updates itself with new data to adjust forecasts.

Among these data, in addition to sales histories, the user can add a layer of market intelligence, user-defined metrics and multi-tier product hierarchies to perform analysis at the level of aggregation required by each customer.

The result is faster reactions to changes to meet customer service objectives.

In short, Demand Planning is :

- Work by alert, focused on items that require it

- Calculation of statistical forecasts from your historical data or other sources

- Managing the introduction of new products

- Promotions management

- Statistical calculation of safety stocks and stock targets

- Multi-user

- Multiple what-if scenarios

- Workflow for monthly validation/publication of a single forecast scenario useful to all levels of the company

Thanks to Demand Planning:

- Adjust your forecasts at will according to the commercial information at your disposal

- Determine the reliability of your forecasts

- Communicate with all company employees

- Gain efficiency with the exception-based management model

- Identify high-value products with ABC classification management

Inventory planning: control your stock levels

The second tool in this module is Inventory Planning, which calculates safety stock levels over a defined period.

Inventory planning anticipates stock levels and ensures the right level of responsiveness to serve customers. Advanced models balance demand with supply, taking into account variability, uncertainty, lead-time and capacity constraints.

In short, Inventory Planning is :

- the ability to carry out safety stock analysis scenarios by varying various important parameters

- shorten cycles, broaden product ranges and become ever more customer-oriented

- current and projected inventory valuation

Thanks to Inventory Planning :

- calculate your target safety stock level according to your defined strategy (manual, service rate, etc.). visualize early phase

Sales & Operations Planning (S&OP) or Plan Industriel et Commercial (PIC) — IBP: Align your activities for optimum performance

Supporting the S&OP process, IBP - Integrated Business Planning - synchronizes and enables the collaboration of S&OP players throughout the company. Various workflow models facilitate the regular reviews required, and the alignment between forecasting, supply and sales operations. Finally, they highlight the various potential imbalances.

In short, IBP is :

- Financial reconciliation and centralization of strategic sales and production information

- Fast, efficient S&OP process management (workflow and alerts)

- Advanced management of simulation scenarios for easy analysis and exchange

- Review of assumptions and amendments

Thanks to IBP :

- simulate an infinite number of scenarios with all the essential financial dimensions,

- you are guided in resolving capacity constraints,

- support inventory, growth and performance objectives.

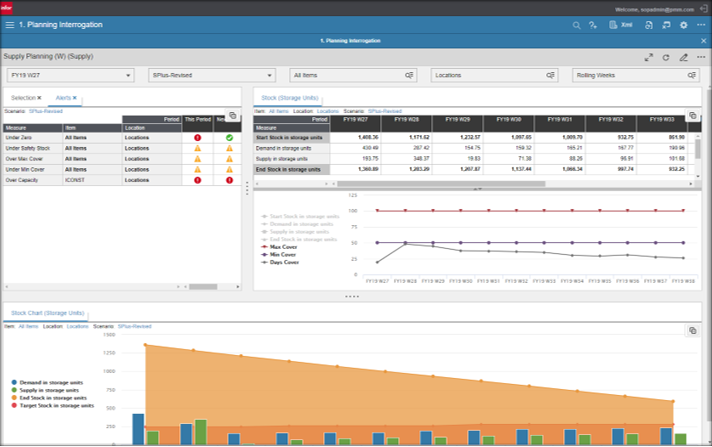

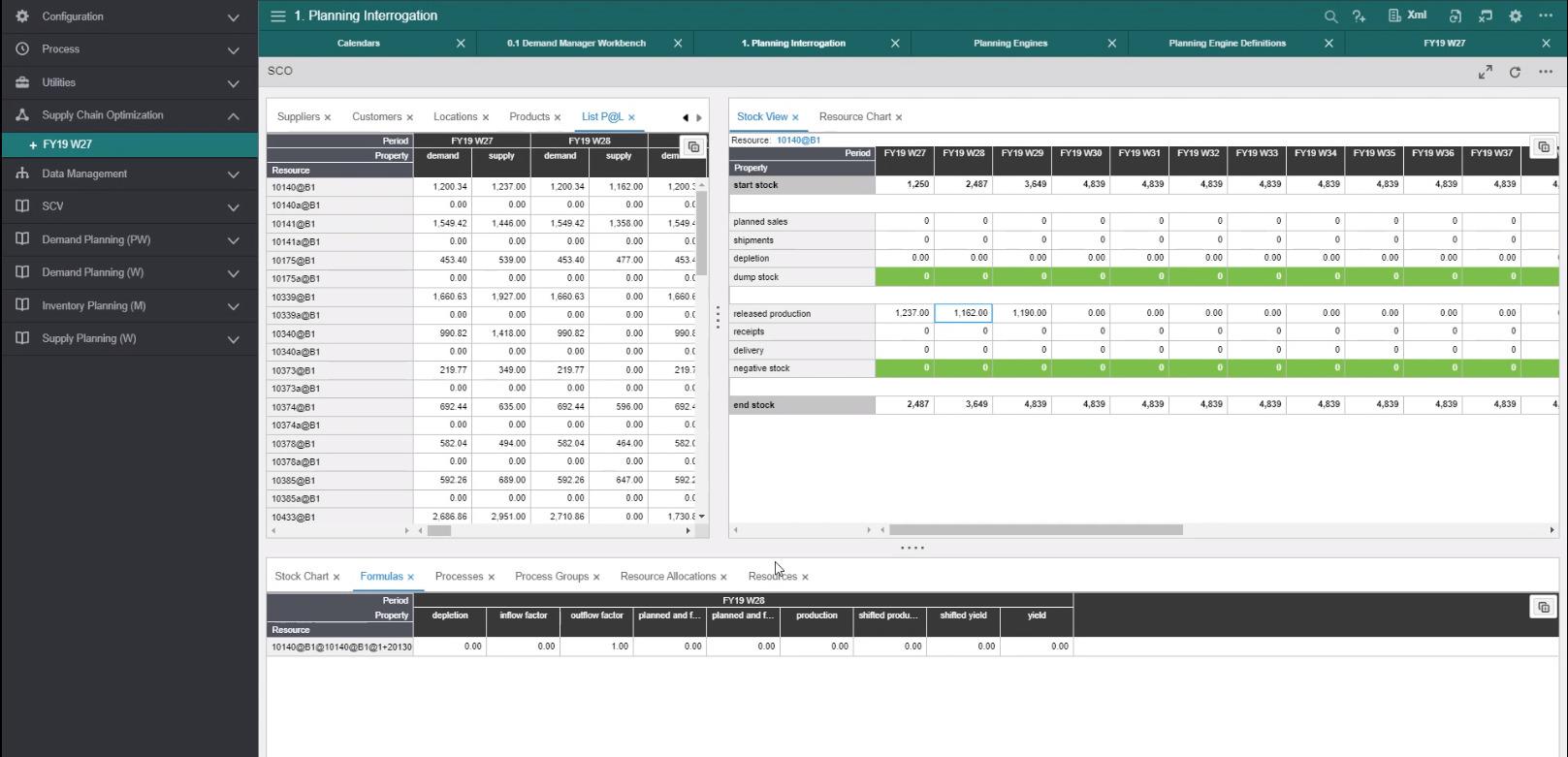

Supply Planning: Efficiently manage your supplies and inventories

Supply Planning: Optimize your resources for a fluid supply chain

In response to the request, the company needs to quickly and accurately assess its capabilities, costs, and different options within the given timeframe. Supply Planning’s highly configurable solution adapts to a company’s changing environment to identify the optimum use of resources across multiple sites, while taking into account lifetimes and cycle times.

In short, Supply Planning is :

- optimized medium- and long-term global planning

- constrained and optimized supply chain planning: capacity, materials, inventory and distribution

- combined replenishment and constrained planning

- creation of scenarios to work out hypotheses before transmitting constrained plans to ERP

Thanks to Supply Planning:

- generate plans that balance your strategy with customer service priorities

- incorporate your distribution, production and procurement alternatives

- use Inventory Planning stock data

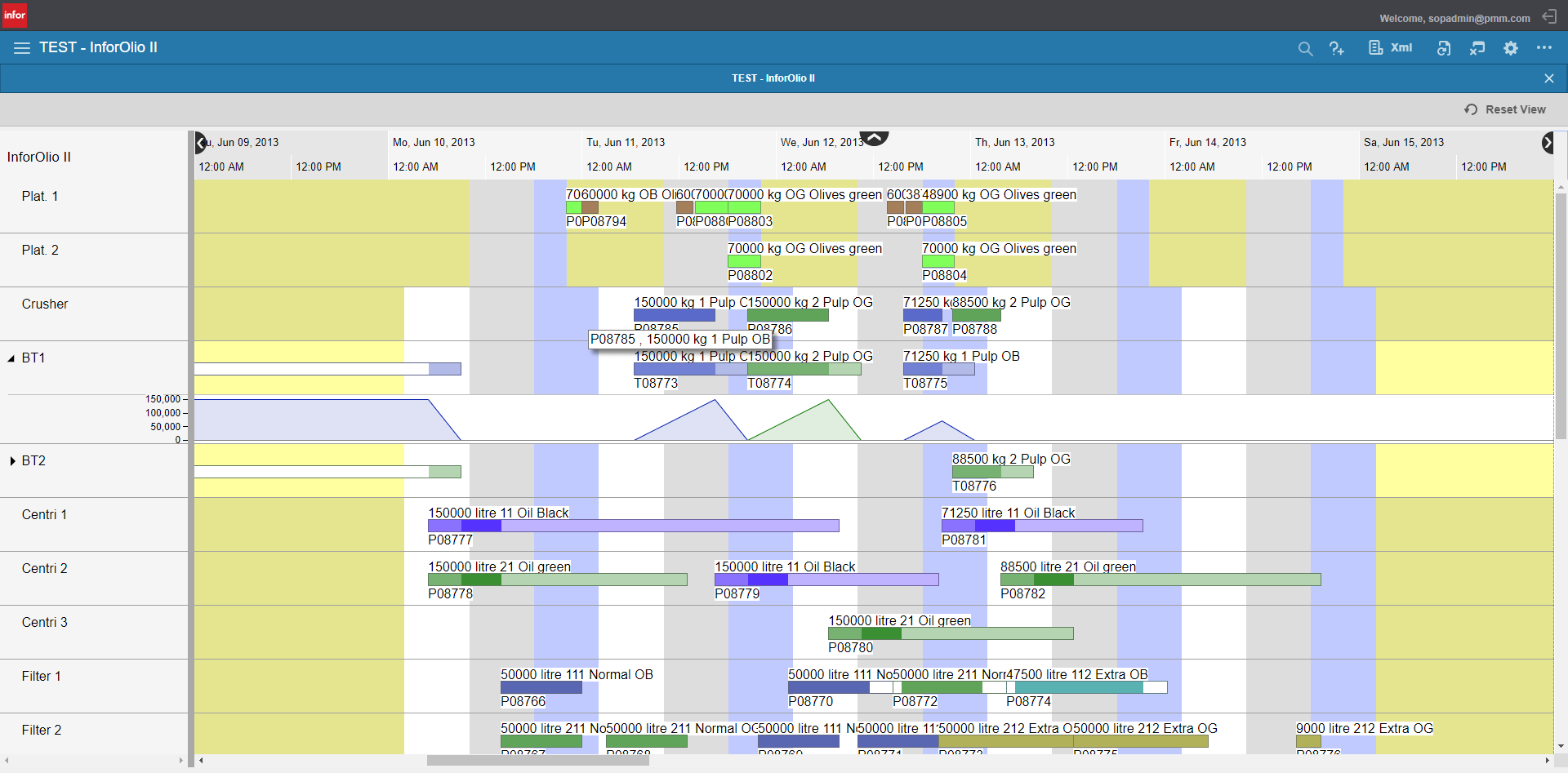

Scheduling — Production Scheduler: Plan your production operations with precision

The Production Scheduler module enables you to schedule your finite-capacity process plants and generate production plans, taking into account all possible production and supply alternatives. All with the aim of obtaining an optimized plan in terms of changeover times, resource utilization and sequence of production orders.

In short, Production Scheduler is :

- Synchronized planning for all plants, by production line and stage

- One-stop management of process, mixing, stabilization, sterilization, intermediate and final storage tanks.

- Sequence optimization: production, changeover times, cleaning

- Pull or push planning

- Respecting scheduled dates and times

- CIP “Cleaning In Place” optimized cleaning scheduling proposal

- A Gantt chart for easy visualization of orders

- Collaborative planning

Thanks to Production Scheduler:

- Analyze your interdependencies, sequences and flows

- Optimize your short production schedules

Transform your supply chain with the Infor Supply Chain Planning software suite

Start to plan your supply chain!

Infor Supply Chain Planning is available in cloud or on-premise versions.

Infor SCP SCM software enables everyone to work together to optimize your entire supply chain network.

We won’t manage your supply chain, but we’ll help you get there!

A team of consultants and project managers put their experience and industry expertise at your service to analyze your processes and optimize them with the Infor Supply Chain Management software suite.

Infor Partner Network a leading provider of solutions for SMI/SMEs, ALOER draws on the dual skills (technology and business) of its employees to support its customers’ growth.

+330478773690